Why Right Turf Protection Flooring Matters for Sports Field Integrity

The growing demand for temporary event flooring on sports fields

Sports field managers are getting squeezed between keeping their grass in good shape and letting in all sorts of events these days. Concerts, festivals, company parties - they're all happening on fields that were built for athletics. According to recent data from stadium operators in 2023, around two thirds of these mixed use facilities now hold at least twelve events outside of regular sports each year. That has created something like a forty percent jump compared to last year in the market for those temporary grass protection systems. What makes this so tricky is finding the right balance between protecting the playing surface and making sure people stay safe. Especially when big stuff like stage setups weighing as much as twelve thousand pounds needs to roll across what can be pretty fragile ground cover without causing damage.

Why protecting natural and synthetic turf is critical during events

Natural grass and artificial turf both get damaged permanently when they don't have adequate protection. Grass fields start losing their roots within about three days of heavy foot traffic, whereas most synthetic surfaces made from polyethylene materials begin to flatten out when pressure goes above five pounds per square inch. A recent study on turf preservation found something pretty shocking: fields left unprotected needed around $740,000 worth of fixes after big events compared to just $23,000 for those that had some form of protection. That means saving almost 97% on repair costs simply by implementing basic protective measures makes good financial sense for facility managers looking at long term expenses.

Case Study: Preventing damage at a major collegiate stadium during concert setup

A Big Ten school recently turned its championship football field into a music festival for three straight days, and somehow managed to keep their expensive hybrid grass intact thanks to those special interlocking turf protectors rated for 8,000 pounds per square foot. The field actually came through unscathed! After checking things out following the event, they found absolutely no soil compaction problems, and the grass bounced back completely within just two weeks. Contrast that with another place nearby where organizers simply laid down regular old plywood boards over their turf during a similar event. That field had serious trouble being playable for half a year afterwards. Makes you wonder why anyone would settle for anything less than proper protection when hosting events on valuable playing surfaces.

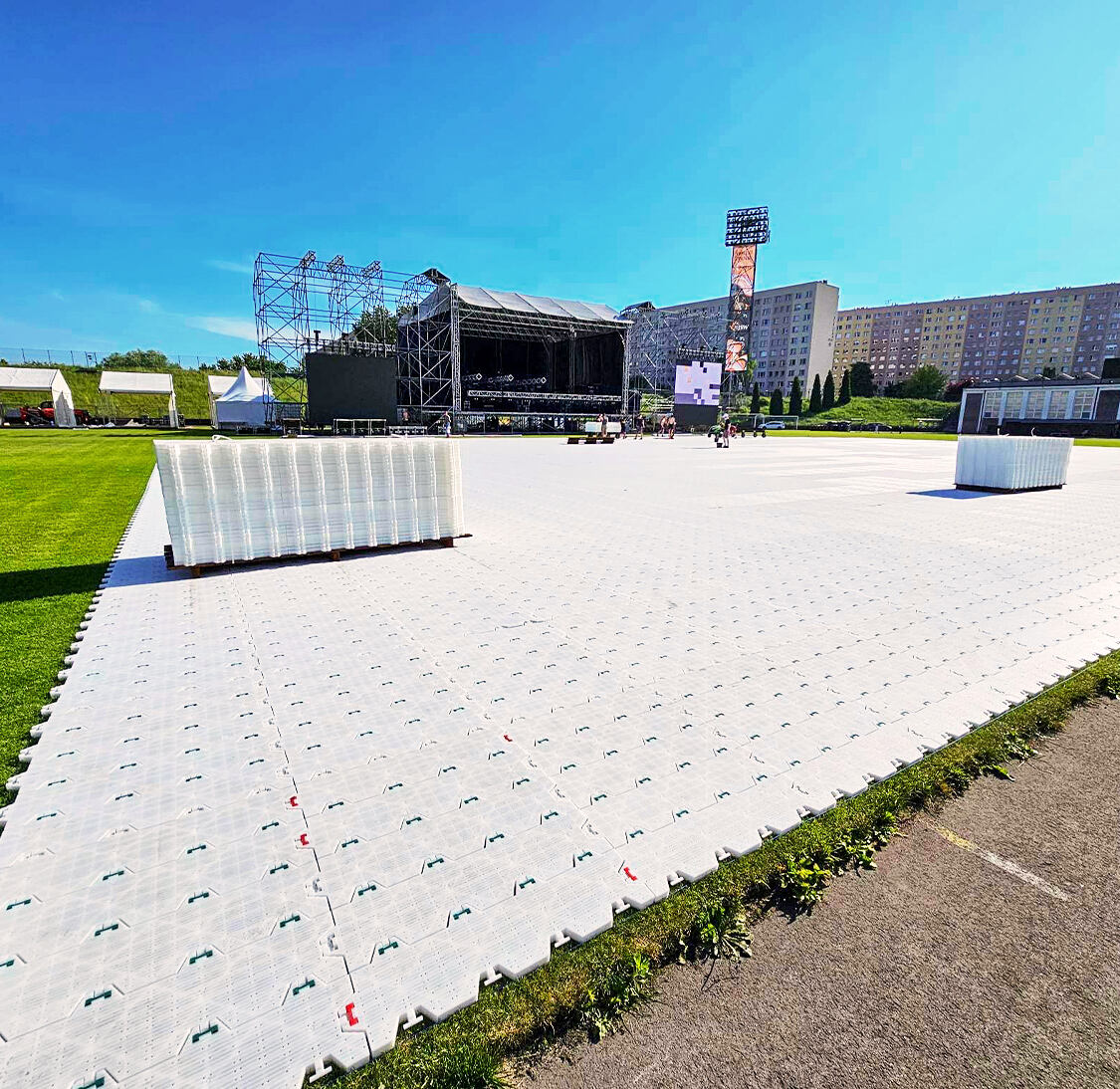

Trend: Rising adoption of modular Right Turf Protection Flooring in outdoor venues

Venues increasingly favor reusable systems rated for 200 events over single-use alternatives. Modular designs made from UV-stabilized polymers now represent 62% of new installations, reducing per-event costs by 83% compared to traditional methods. Their rapid deployment—covering up to one acre in two hours—makes them ideal for back-to-back scheduling.

Key Material and Structural Factors in Right Turf Protection Flooring Selection

How Pile Height Influences Load Distribution and Surface Protection

The height of the pile, which refers to how long those grass fibers stand up, plays a big role in how weight gets distributed across surfaces. When we talk about shorter piles around 8 to 10 millimeters tall, they provide much firmer ground for things like staging equipment but don't offer much give or cushion. On the flip side, longer piles measuring approximately 12 to 15 mm do a far better job at absorbing shocks from heavy machinery or when lots of people walk over them. Research conducted last year showed some interesting results too. They discovered that mixing different pile heights in areas where there's lots of foot traffic actually cut down on turf compression by nearly a third compared to having everything at the same level throughout.

Comparing Fiber Types: Polypropylene, Polyethylene, and Nylon for Event Durability

Material selection determines resistance to abrasion, UV exposure, and moisture retention:

| Fiber Type | Tensile Strength | UV Resistance | Moisture Absorption | Best For |

|---|---|---|---|---|

| Polypropylene | 350-400 MPa | Moderate | 0.01% | Short-term concerts |

| Polyethylene | 250-300 MPa | High | 0.005% | Multi-day festivals |

| Nylon | 500-600 MPa | Low | 4.5% | Heavy machinery pathways |

Polyethylene dominates outdoor applications due to its weather resistance and flexibility, while nylon's strength suits industrial uses despite higher maintenance demands.

The Role of Infill Density in Stabilizing Turf Under Heavy Foot Traffic

The turf needs something inside it to hold everything together, so we typically put in stuff like silica sand or rubber bits that make up around three quarters to almost nine tenths of the total volume. When the stuff inside weighs more than about 25 kilograms per cubic meter, the field stays firm even when hundreds of people walk all over it during games, though water might drain slower than ideal. Most sports facilities these days go for hybrid mixes where they combine roughly two thirds sand with one third rubber particles. This approach works particularly well for stadiums hosting multiple matches close together, since tests at actual venues showed this method cuts down on soil loss near the roots by nearly half compared to traditional methods.

Synthetic Grass vs. Performance Turf: Navigating Durability Debates in High-Impact Events

While synthetic grass mimics natural aesthetics, performance turf includes:

- Reinforced backing layers resistant to tears up to 2,000N

- Cross-linked polymers minimizing thermal expansion

- Pre-coated fibers reducing sand displacement

High-impact venues report 58% fewer surface replacements when using performance turf for events exceeding 72 hours.

Performance Metrics: Shock Absorption, Traction, and Impact Resistance

Why Shock Absorption Is Vital for Athlete Safety and Subfloor Protection

Shock absorption systems can cut down on those sudden impact forces by as much as 70 percent. This protects players' joints from wear and tear while also saving money on damaged flooring underneath. Instead of letting all that force travel straight through, good shock absorption spreads out the energy. The result? Fewer ACL injuries, which matters a lot for contact sports such as American football and soccer where players are constantly changing direction. Plus, fields stay in better condition longer since heavy equipment and stage setups don't create those expensive repair problems from concentrated weight spots.

Measuring G-Max Values and Force Reduction in Padded Turf Systems

G-max testing measures deceleration force during impact, with optimal Right Turf Protection Flooring maintaining values below 120 (typical synthetic turf ranges from 90–150). Force reduction should exceed 50% under ASTM F1936 standards. Modern systems achieve this through layered padding and optimized infill, balancing safety with surface stability.

Case Study: Reducing Injury Rates With Shock-Absorbent Flooring at Youth Tournaments

Midwest regional soccer games saw something interesting happen in 2023 when they installed these new shock absorbing floors. Ankle injuries dropped by around 40% compared to previous seasons. Soccer players actually mentioned that their feet felt better on rainy days too, which makes sense given how slippery regular fields get. The grounds crew was also surprised because there wasn't any noticeable wear on the turf even after nearly two weeks straight of games going on without stopping. With both player safety and field maintenance improvements, it's no wonder why most NCAA colleges (about three out of four) have started using similar flooring options across their sports complexes.

Optimizing Traction Without Compromising Turf Protection

Texture molded surfaces offer a pretty good friction range between 0.6 and 0.8 which works great for cleats to get proper grip without causing too much shear force that ends up damaging the grass fibers underneath. Many modern designs feature cross hatch patterns in their drainage systems. These help keep players from slipping when it rains but also stop too much water from soaking into the ground below where it could cause problems. Looking at what actually works best in the field, most experts agree that combining adjustable stud setups with special hybrid polymers gives the right mix of grip strength and surface protection. This approach has become increasingly popular among facility managers who want both performance and longevity from their turf installations.

Durability, Maintenance, and Longevity of Right Turf Protection Flooring

Proper maintenance extends the lifespan of Right Turf Protection Flooring by 40% compared to reactive repair strategies (Turf Industry Report 2024). Implementing consistent care enhances both durability and cost efficiency.

Cleaning Protocols and Debris Management Post-Event

Organizers should clean within 24 hours of equipment removal:

- Use high-pressure air jets (≥ 80 PSI) to remove embedded debris

- Apply pH-neutral enzymatic cleaners for organic spills like food or drinks

- Deploy debris containment grids at entry/exit points during teardown

Neglecting cleaning accelerates wear by 33%, especially around stage perimeters and concession areas.

UV Stabilization and Drainage Rate

Quality Right Turf Protection Flooring includes:

- UV inhibitors tested for over 10,000 hours of sun exposure

- Hydraulic-grade drainage capable of handling ≥ 250 gallons per square foot per hour

| Material | UV Resistance Rating | Drainage Capacity |

|---|---|---|

| Polypropylene | Class 2 | 200 GPH |

| Crosslinked PE | Class 1 | 275 GPH |

This combination prevents warping during summer events and reduces waterlogging risks at rainy outdoor functions.

Installation and Maintenance Tips

To maximize reuse cycles:

- Lay protective sheeting before placing modular tiles

- Use weighted spacers (≥ 5 lbs/ft²) to prevent shifting under load

- Store rolled sections vertically in climate-controlled trailers

Correct alignment during setup reduces seam degradation by 60% over ten uses—essential for venues with weekly events.

Portability, Reusability, and Cost-Effectiveness in Event Flooring Solutions

Modular Interlocking Systems for Rapid Deployment and Retrieval

Modern systems feature interlocking modular panels enabling crews to cover 10,000 sq. ft. in under three hours. Lightweight (15–22 lbs per panel), they have tapered edges for seamless assembly and tool-free disengagement, cutting labor costs. Unlike rolled flooring, modular designs eliminate wrinkles and adapt easily to irregular field shapes.

Lifecycle Analysis: Number of Uses Before Performance Degradation

High-grade turf protection flooring maintains integrity for 400+ event cycles when properly maintained, based on third-party testing of UV-stabilized polyethylene systems. Performance thresholds vary by event type:

| Event Type | Safe Reuse Threshold | Critical Failure Point |

|---|---|---|

| Concerts/Festivals | 120–150 cycles | 200+ cycles |

| Trade Shows | 200–220 cycles | 300+ cycles |

Regular inspection of interlocks and surface warping helps extend service life before recycling.

Calculating ROI Based on Reusability, Storage, and Event Frequency

Organizations hosting 12+ annual events achieve a 34% faster ROI by purchasing rather than renting, according to event management research. Key financial considerations include:

- Break-even point: (System Cost – Rental Fees Per Event) / Events Per Year

- Storage economics: $0.85/sq.ft annual storage vs $1.20/sq.ft rental delivery fees

- Damage liability: Owner-managed repairs vs vendor insurance premiums

Checklist: Matching Right Turf Protection Flooring to Event Type and Field Longevity Goals

- Assess event size (attendees per sq.ft) and duration (≥72hr vs multi-week)

- Confirm panel thickness (≥22mm for heavy equipment; 15mm for foot traffic)

- Require ASTM F2157-09 certification for synthetic turf compatibility

- Verify drainage rates (1,000 inches/hr for outdoor festivals)

FAQ

What is Right Turf Protection Flooring?

Right Turf Protection Flooring is a specialized system designed to protect sports fields during events, maintaining the integrity of the turf whether it be natural or synthetic.

How does turf protection flooring help reduce repair costs?

Turf protection flooring reduces repair costs by preventing damage from heavy equipment and foot traffic, ensuring the surface remains intact after events. Studies show a 97% cost reduction in repairs when using adequate protection.

What materials are best for turf protection?

Polyethylene is preferred for outdoor events due to its high UV resistance and low moisture absorption, whereas nylon is suited for heavy machinery pathways because of its high tensile strength.

How is shock absorption achieved in turf protection systems?

Shock absorption is achieved by layering padding and optimized infill, which spreads out impact forces, protecting players and the turf during intense sports activities.

Why are modular interlocking systems beneficial for events?

Modular interlocking systems allow rapid deployment and removal, are lightweight, adapt to irregular field shapes, and reduce labor costs by eliminating the need for heavy tools during setup.

Table of Contents

- Why Right Turf Protection Flooring Matters for Sports Field Integrity

-

Key Material and Structural Factors in Right Turf Protection Flooring Selection

- How Pile Height Influences Load Distribution and Surface Protection

- Comparing Fiber Types: Polypropylene, Polyethylene, and Nylon for Event Durability

- The Role of Infill Density in Stabilizing Turf Under Heavy Foot Traffic

- Synthetic Grass vs. Performance Turf: Navigating Durability Debates in High-Impact Events

- Performance Metrics: Shock Absorption, Traction, and Impact Resistance

- Durability, Maintenance, and Longevity of Right Turf Protection Flooring

- Portability, Reusability, and Cost-Effectiveness in Event Flooring Solutions

- FAQ

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

SV

SV

CA

CA

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

MN

MN

MY

MY

UZ

UZ