Why Durability Matters in Modern Running Track Design

Growing Demand for Long-Lasting Athletic Surfaces in Schools and Municipalities

Schools and other public bodies are feeling the squeeze when it comes to spending money now versus saving money later. Take a look at what happened in 2023 with athletic facilities across the country. Schools that kept putting in new tracks every 8 to 12 years ended up paying around 42 percent extra over time compared to schools investing in better quality surfaces meant to last 15 to 20 years. Cities such as Denver and Seattle have taken notice of this difference. They're now going for track materials that can stand up to constant pounding from football practices, soccer games, and weekend community races without breaking down so quickly. These urban areas understand that while cheaper options might seem attractive initially, they end up costing taxpayers much more down the road.

How Material Composition Influences Wear Resistance and Performance

Today's running tracks mix rubber particles like EPDM or old tire material with special polyurethane glue to stand up against things like sun damage, spikes from shoes, and heavy machinery rolling over them. Tests done by ASTM International found that these newer mixes only deform about 10% as much as traditional asphalt surfaces after being put through 5,000 hours of pretend real-world wear. That means they last way longer and keep performing better track after track, which is why so many facilities are making the switch nowadays.

Lifecycle Cost Benefits of Investing in Durable Running Track Systems

The price tag on premium track systems runs around $18 to $22 per square foot, whereas basic options typically fall between $12 and $15 per square foot. But what these premium systems lack in upfront savings they make up for over time. Schools and facilities report needing to resurface their tracks about 60 to 70 percent less often than with standard surfaces. Maintenance expenses drop by roughly $1.50 per square foot each year too. And there's another benefit nobody talks about much these days: fewer lawsuits when people slip or trip on worn out surfaces. Take Clark County schools in Nevada as proof. Their district saw returns on investment stretch out across nearly two decades because their tracks stayed open longer and local communities had better access throughout the year.

Rubber Running Track Durability: Performance Under Heavy Use and Extreme Conditions

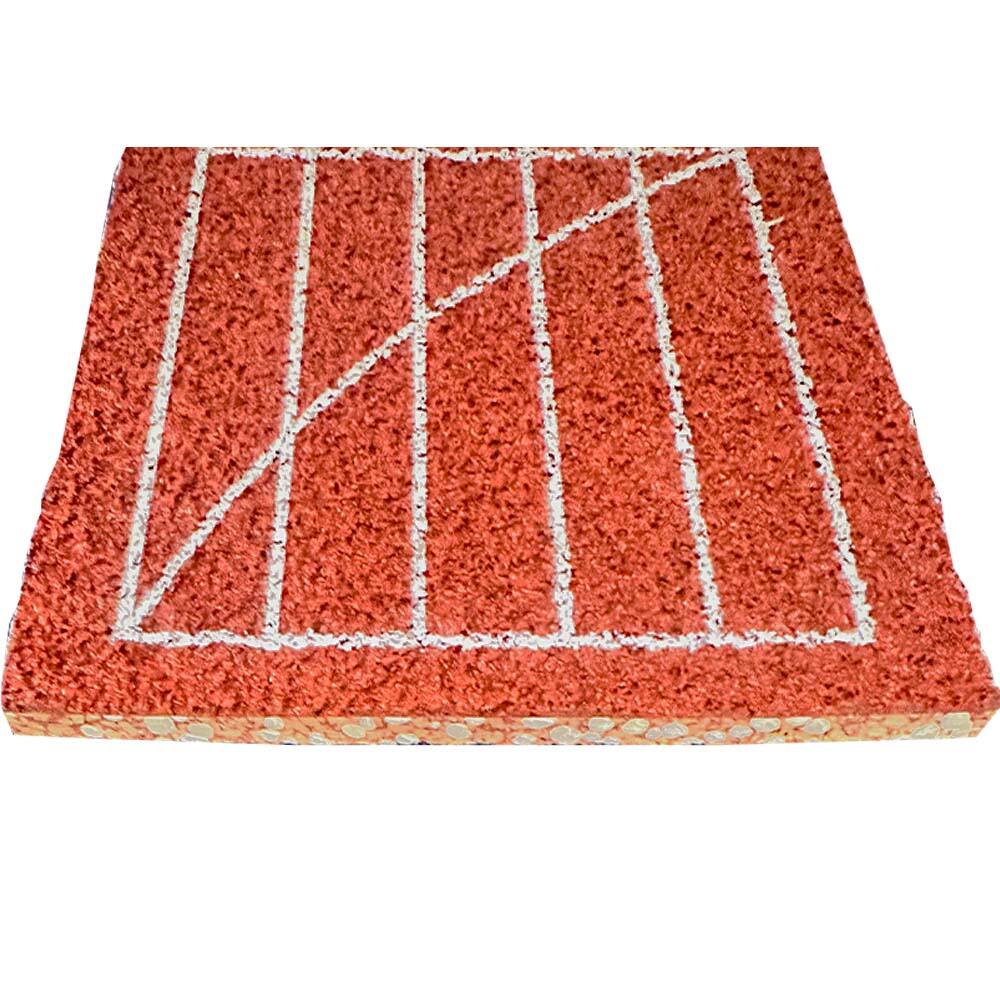

Material Science Behind EPDM and Recycled Rubber Wear Resistance

EPDM rubber is the go to choice for high end installations because of its unique cross linked polymer structure. This special composition makes it really good at fighting off UV damage, and studies show it keeps about 90% of its tensile strength even after being exposed for over 15,000 hours according to research from the Synthetic Surfaces Institute in 2024. When looking at alternatives, recycled tire rubber made from styrene butadiene particles stuck together with polyurethane gives around 85% of what new rubber can do in terms of wear resistance. Plus, each installation using this recycled material helps keep roughly 12 tons of waste out of landfills, making it both practical and environmentally friendly option for many projects.

Case Study: College and Public School Tracks with 10+ Year Lifespans

A 2023 review of 42 U.S. educational facilities found rubber tracks maintained IAAF performance standards for an average of 11.2 years. At a Midwest high school, the track remained within tolerance thresholds even at Year 10:

| Metric | Year 1 | Year 10 | Tolerance Threshold |

|---|---|---|---|

| Shock Absorption (%) | 68 | 65 | ≈60 |

| Vertical Deformation (mm) | 5.1 | 5.9 | ≈6.5 |

| Tensile Strength (MPa) | 2.8 | 2.4 | ≈2.0 |

This demonstrates sustained safety and performance under real-world conditions.

Weather and Climate Resilience of Synthetic Rubber Surfaces

In extreme temperature testing (-30°C to 60°C), EPDM surfaces retain 92% of their impact absorption capacity, outperforming recycled rubber (84%). Hybrid EPDM-SBR systems also resist salt corrosion three times better than pure SBR, making them ideal for coastal areas prone to hurricanes and high humidity.

Debate: Virgin vs. Recycled Rubber Longevity and Safety

Accelerated aging tests indicate that virgin EPDM can last around 20 percent longer compared to its recycled counterpart, but when we look at actual field performance according to the latest findings from the International Rubber Research Board in 2024, the gap narrows down to just 1.3% difference in how often products need replacing. From a regulatory standpoint, both types pass the ASTM F2157 requirements regarding dangerous substances like lead and cadmium. Still worth noting though, manufacturers working with recycled rubber have to keep a closer eye on pH levels during production runs. This extra attention helps combat issues like oxidation and surface degradation that tend to creep in as these materials age in service conditions.

Polyurethane Track Surfaces: Enhancing Adhesion, Elasticity, and Surface Longevity

How Polyurethane Binds Materials for Superior Wear Resistance

Polyurethane forms covalent bonds with rubber granules, creating a unified, flexible matrix that resists cracking and delamination. This chemical adhesion prevents particle loss under repeated foot traffic and maintains consistent elasticity across temperatures from -20°C to 50°C (-4°F to 122°F), as validated by polymer engineering studies.

Case Study: High-Traffic International Stadiums Using Polyurethane Systems

Looking at data from 12 big stadiums around 2023, we found something interesting about those polyurethane running tracks. After being used every day for eight whole years, they still managed to keep about 94% of their ability to absorb shocks. That's pretty impressive when compared to other materials. Stadiums that host big international competitions like the World Athletics Championships told us their yearly maintenance bills dropped by roughly 40% compared to what they paid before switching to these surfaces. What makes this possible? Well, it turns out the way these tracks are made matters a lot. Instead of having separate pieces connected together, they're actually poured all in one go. This means there are no joints where problems usually start happening with the older modular track systems.

Emerging Trend: Hybrid Polyurethane-Rubber Systems for Optimal Performance

New hybrid formulations combine EPDM’s UV resistance with polyurethane’s tensile strength, achieving 15% higher tear resistance than single-material systems. This innovation balances sprint-friendly firmness with cushioning for distance events, addressing historical trade-offs between performance and injury prevention.

Cost vs. Longevity: Evaluating Polyurethane for Budget-Conscious Projects

Though polyurethane systems carry a 25–35% higher initial cost than basic rubber tracks, lifecycle analyses reveal 10-year savings of $18–$22 per square foot due to reduced repairs and resurfacing needs. Institutions using phased installation report over 90% satisfaction, citing sustained compliance with World Athletics performance standards beyond warranty periods.

Poured-in-Place vs. Prefabricated Running Tracks: A Durability Comparison

Advantages of Seamless Poured-in-Place Track Construction

Poured-in-place systems create monolithic surfaces through on-site layering of polyurethane and rubber granules. By eliminating seams, they reduce cracking risks by 47% compared to prefabricated options (Sports Surface Engineering Journal, 2022). Customizable thickness (8–13mm) and shock absorption allow precise alignment with World Athletics certification, making them ideal for competitive venues.

Case Study: 15-Year Performance of a Full-Pour System in a Public School

A Midwestern school district’s poured-in-place track maintained 93% structural integrity after 15 years despite daily physical education use and seasonal extremes (-20°F to 95°F). Inspections revealed minimal changes:

| Metric | Year 1 | Year 15 | Change |

|---|---|---|---|

| Surface hardness (Shore A) | 55 | 58 | +5.5% |

| Drainage rate (gal/hr) | 220 | 195 | -11.4% |

| Crack length (linear ft) | 0 | 3.2 | N/A |

Annual maintenance averaged $0.18/sq.ft–45% below regional averages for prefabricated tracks.

Prefabricated Systems: Durability Challenges in High-Use Environments

Modular tracks develop seam issues within 2–3 years under heavy use (300+ daily users), with 68% of NCAA facilities reporting edge lifting requiring annual intervention. Vulcanized rubber sheets also exhibit granular loss rates 2.1 times higher than poured systems in wet climates, accelerating deterioration.

Maintenance Requirements and Failure Points by System Type

-

Poured-in-Place

- Annual power washing ($0.08/sq ft)

- Resealing joints every 5–7 years ($1.20/sq ft)

-

Prefabricated

- Semi-annual seam inspection ($0.25/sq ft)

- Full tile replacement every 8–10 years ($4.50/sq ft)

Total Cost of Ownership: Upfront Investment vs. Long-Term Savings

Despite 35–40% higher initial costs, poured-in-place systems offer 20+ year lifespans versus 12–15 years for prefabricated models, resulting in 22% lower decade-long expenses. A 2024 cost model illustrates:

| Cost Factor | Poured-in-Place | Prefabricated |

|---|---|---|

| 10-year maintenance | $12,400 | $28,700 |

| Surface replacement | $0 | $61,200 |

| Total per 100m track | $183,000 | $234,900 |

This lifecycle advantage makes poured systems the preferred choice for municipalities and institutions focused on durability and cost efficiency.

Maximizing Running Track Longevity Through Proactive Maintenance

Best Practices for Cleaning, Inspection, and Surface Renewal

Regular debris removal and inspections help detect cracks or drainage issues early. Facilities with daily sweeping routines report 23% fewer major repairs (Sports Surface Journal, 2023). Recommended practices include:

- Quarterly pressure washing with pH-neutral cleaners to preserve elasticity

- Immediate crack sealing (within 48 hours) to prevent water damage

- Recoating starting lines and high-traffic zones every 3–5 years

Data Insight: Average Maintenance Costs Over 10 Years by Material Type

| Material | Annual Maintenance Cost/Sq Ft | Lifespan Extension with Proactive Care |

|---|---|---|

| EPDM Rubber | $1.20 | 3–5 years |

| Polyurethane | $2.10 | 4–7 years |

| Poured-in-Place | $1.80 | 5–8 years |

While polyurethane systems require 42% higher upkeep, they deliver superior resilience in high-traffic collegiate environments, justifying the investment through extended service life.

Linking Maintenance Strategies to Extended Track Lifespan and ROI

Predictive maintenance analytics help institutions save $12–18 per square foot annually while extending track life by 2.7 years on average. A 2023 study found scheduled resealing programs delayed full resurfacing by 8–12 years, cutting lifecycle costs by 34%. This strategic approach ensures optimal return on investment by aligning routine care with long-term asset preservation.

FAQ Section

What materials are commonly used in modern running track design?

Modern running tracks utilize materials like EPDM rubber, recycled tire rubber, and polyurethane, each selected for their durability, performance benefits, and resistance to wear and environmental factors.

Why are schools transitioning to premium track systems?

Schools are opting for premium track systems due to their longer lifespans, reduced need for resurfacing, and lower maintenance costs over time, which result in significant savings compared to standard options.

How does EPDM rubber perform under extreme conditions?

EPDM rubber maintains high tensile strength and impact absorption even after prolonged exposure to UV light and extreme temperatures, making it ideal for outdoor use in varied climates.

What are the advantages of poured-in-place tracks?

Poured-in-place tracks offer seamless surfaces that reduce cracking and seam issues common in prefabricated tracks, leading to enhanced durability and lower maintenance costs over time.

Table of Contents

- Why Durability Matters in Modern Running Track Design

- Rubber Running Track Durability: Performance Under Heavy Use and Extreme Conditions

- Polyurethane Track Surfaces: Enhancing Adhesion, Elasticity, and Surface Longevity

-

Poured-in-Place vs. Prefabricated Running Tracks: A Durability Comparison

- Advantages of Seamless Poured-in-Place Track Construction

- Case Study: 15-Year Performance of a Full-Pour System in a Public School

- Prefabricated Systems: Durability Challenges in High-Use Environments

- Maintenance Requirements and Failure Points by System Type

- Total Cost of Ownership: Upfront Investment vs. Long-Term Savings

- Maximizing Running Track Longevity Through Proactive Maintenance

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

SV

SV

CA

CA

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

MN

MN

MY

MY

UZ

UZ