ပြေးလမ်းမျက်နှာပြင်၏ တည်ငြိမ်မှုကို ထိန်းသိမ်းရန် ပုံမှန်သန့်ရှင်းခြင်း

အမှိုက်အိမ်မက်များ စုပုံမှုကို ကာကွယ်ရန် နေ့စဉ်နှင့် အပတ်စဉ် သန့်ရှင်းရေး အလေ့အကျင့်များ

အစိမ်းရောင်ပိုင်းဆိုင်ရာ အရာဝတ္ထုများဖြစ်သော အရွက်များ၊ ခြောက်လှန့်ထားသော မြက်ပင်များနှင့် အခြားသော ပစ္စည်းများကို ပြိုင်ပွဲပြေးလမ်းများမှ ပုံမှန်သန့်ရှင်းရေးပြုလုပ်ခြင်းဖြင့် ဖယ်ရှားပေးခြင်းသည် ၎င်းတို့၏ ရေရှည်တည်တံ့မှုအတွက် အလွန်အရေးပါပါသည်။ ပြိုင်ပွဲပြေးလမ်းများပေါ်တွင် ပစ္စည်းများ နက်ရှိုင်းစွာ ဝင်ရောက်မှုမဖြစ်စေရန် နူးညံ့သော ဘရပ်ရှ်များဖြင့် မျက်နှာပြင်များကို ပုံမှန်သန့်စင်ခြင်းသည် ကောင်းမွန်သော နေ့စဉ်အလေ့အကျင့်ဖြစ်ပါသည်။ တစ်ပတ်လျှင် တစ်ကြိမ် အဆောက်အဦများတွင် 600 psi အများဆုံးသာ ဖိအားမြင့်ရေဖြန်းစက်ဖြင့် သန့်စင်ရေးပြုလုပ်ပေးသင့်ပါသည်။ ထိုသို့ပြုလုပ်ခြင်းဖြင့် အောက်ခံတွင်ရှိသော ဈေးကြီး ပေါလီယူရီသိန်း အထူးပြုလုပ်ထားသော အလ пок်များ သို့မဟုတ် ရာဘာအလွှာများကို ပျက်စီးစေခြင်းမရှိဘဲ စုပုံနေသော အညစ်အကြေးများကို ဖယ်ရှားနိုင်ပါသည်။ ဤကဲ့သို့သော ပုံမှန်သန့်ရှင်းရေး အလေ့အကျင့်ကို လိုက်နာသော ကျောင်းများနှင့် ပန်းခြံများသည် သန့်ရှင်းရေးကို လျစ်လျူရှုထားသော သို့မဟုတ် မမှန်မကန်ပြုလုပ်သော နေရာများနှင့် နှိုင်းယှဉ်ပါက ပြိုင်ပွဲပြေးလမ်းများပေါ်တွင် အသုံးပြုမှုကြောင့် ပျက်စီးမှုကို တစ်ဝက်ခန့်သာ ခံစားရပါသည်။ ဘတ်ဂျက်များ ကန့်သတ်ချက်ရှိပြီး အစားထိုးကုန်ကျစရိတ်များ တိုးလာသည့်အခါတိုင်း နှစ်တိုင်းအတွက် ဤကွာခြားမှုများသည် ပိုမိုကြီးမားလာပါသည်။

ရေပိတ်ဆို့မှုကို ကာကွယ်ရာတွင် ရေစီးဆင်းမှု ထိန်းသိမ်းခြင်း၏ အရေးပါမှု

အားကစားကွင်းများတွင် ရေထွက်ပိုက်များပိတ်ဆို့ခြင်းသည် လမ်းကြောင်းပြဿနာများ၏ ၆၀ ရာခိုင်နှုန်းခန့်ကို ဖြစ်ပေါ်စေကြောင်း လေ့လာမှုများက ပြသထားပါသည်။ တစ်လလျှင် တစ်ကြိမ် အပြင်ဘက်ရေစီးပိုက်များနှင့် ရေကောက်အိုင်များကို ရှင်းလင်းထားခြင်းဖြင့် ရေစီးဆင်းမှုကို ကောင်းမွန်စေပါသည်။ မြေအောက်ရှိ ပိုက်များကို ခြောက်လတစ်ကြိမ် ကင်မရာများဖြင့် စစ်ဆေးခြင်းဖြင့် စနစ်အားလုံး ပုံမှန်လုပ်ဆောင်နေကြောင်း သေချာစေပါသည်။ ထိုကဲ့သို့သော ထိန်းသိမ်းမှုများ မပြုလုပ်ပါက ရေစုပ်များသည် မျက်နှာပြင်ကို ကွေးညွှတ်စေပြီး အောက်ခြေရှိပစ္စည်းများကို ဖျက်စီးနိုင်ပါသည်။ နှစ်တစ်နှစ်လုံးတွင် မုတ်သုံများ မကြာခဏ ရွာသွန်းသော ဒေသများတွင် ဤအချက်သည် အထူးအရေးပါပါသည်။

စက်မှုတိုက်သန့်ရေးစက်များနှင့် ကျွမ်းကျင်ပစ္စည်းများကို အသုံးပြု၍ တစ်နှစ်တစ်ကြိမ် နက်ရှိုင်းစွာ သန့်ရှင်းရေးပြုလုပ်ခြင်း

ပရော်ဖက်ရှင်နယ်အဆင့် သန့်ရှင်းရေးပြုလုပ်ခြင်းဖြင့် မျက်နှာပြင် ပွတ်တိုက်မှု ဂုဏ်သတ္တိများကို မူရင်းအတိုင်း ပြန်လည်ရရှိစေပါသည်။ အတည်ပြုထားသော နည်းပညာပညာရှင်များသည် စက်မှုတိုက်သန့်ရေးစက်များကို pH အားဖြင့် သင့်တော်သော သန့်စင်ဆေးများနှင့် တွဲဖက်၍ အောက်ဆီဒိုင်းဖြစ်နေသော ရာဘာများနှင့် ဇီဝဖြစ်ထွန်းမှုများကို ဖယ်ရှားပေးပါသည်။ တစ်နှစ်တစ်ကြိမ် နက်ရှိုင်းစွာ သန့်ရှင်းရေး ပြုလုပ်သည့် စနစ်များကို အသုံးပြုသော အဆောက်အဦများသည် လမ်းကြောင်း၏ သက်တမ်းကို ၃ မှ ၅ နှစ်အထိ တိုးမြှင့်နိုင်ပြီး ကုန်ကျစရိတ်များသော မျက်နှာပြင်ပြန်ဖုံးအုပ်ခြင်း စီမံကိန်းများကို နှေးကွေးစေပါသည်။

ပြေးလမ်းကြောင်းပျက်စီးမှုများကို စောစီးစွာ ရှာဖွေတွေ့ရှိရန် ပုံမှန်စစ်ဆေးခြင်း

မျက်နှာပြင်အရွေ့အပြောင်းများနှင့် သုံးစွဲမှုပုံစံများကို ဖော်ထုတ်ရန် တစ်ပတ်တစ်ခါ လမ်းကြောင်းလိုက် စစ်ဆေးခြင်း

တစ်ပတ်လျှင်တစ်ကြိမ် စနစ်ကျစွာ စစ်ဆေးခြင်းဖြင့် ပြဿနာကြီးလာမည်မတိုင်မီ မျက်နှာပြင်ပေါ်ရှိ အနုအယားအကွဲအစက်များကို ဖော်ထုတ်နိုင်ပါသည်။ အဆောက်အဦစီမံခန့်ခွဲသူများသည် အောက်ပါတို့ကို ပြုလုပ်သင့်ပါသည်-

- လမ်းကြောင်းအတွင်း (အထူးသဖြင့် လူသွားလမ်းများ၊ ကွင်းဆောင်လုပ်ငန်းနေရာများ) ၁/၈" ကျယ်ရှိသော ကွဲအက်မှုများကို စကင်ဖတ်ခြင်း

- လမ်းကြောင်းပေါ်ရှိ အမှတ်အသားများကို ထိခိုက်စေသော UV ဖြစ်စေသည့် ဖျော့သွားမှုပုံစံများကို မှတ်တမ်းတင်ခြင်း

- တံဆိပ်တံဖြင့် တိုင်းတာ၍ ၃မီလီမီတာ နက်ရှိုင်းမှုရှိသော နိမ့်ကျနေသည့်နေရာများကို မြေပုံဆွဲခြင်း

- အစွန်းတွန်းကန်များ သို့မဟုတ် ကမ်းပါးများ လွတ်ထွက်နေခြင်းကို သတိပေးအမှတ်အသားပြုခြင်း

ပြုပြင်ထိန်းသိမ်းမှုကို တုံ့ပြန်ဆောင်ရွက်ခြင်းနှင့် နှိုင်းယှဉ်ပါက စနစ်ကျသော စစ်ဆေးစစ်နှဲမှုပုံစံသည် ပြုပြင်မှုကုန်ကျစရိတ်ကို ၁၈–၃၄% လျှော့ချပေးနိုင်ပါသည် (Sports Surface Analytics 2023)

| စစ်ဆေးမှုအာရုံစိုက်မှု | ကိရိယာ | လုပ်ဆောင်မှု နိမ့်နိမ့်အဆင့် |

|---|---|---|

| မျက်နှာပြင်ပြန်တက်မှု | ဒျူရိုမီတာဂေ့ | အခြေခံကနေ ၁၅% ပြောင်းလဲမှု |

| ရေစိမ့်ဝင်မှု | အစိုဓာတ်ထိန်းကိရိယာ | မည်သည့်အချိန်တွင်မဆို ၂၅% ပြည့်နှက်မှု |

| တိုက်ခိုက်မှု ခံနိုင်ရည် | ကလက်ဂ်တုတ် | ၇၀ အောက် ဂရဗျိတီစကို |

ထိန်းသိမ်းမှု ခြေရာခံခြင်းနှင့် ကိုက်ညီမှုအတွက် စစ်ဆေးမှုတွေ့ရှိချက်များ မှတ်တမ်းတင်ခြင်း

ဒစ်ဂျစ်တယ်မှတ်တမ်းများတွင် တည်နေရာအမှတ်အသားပြုထားသော ဓာတ်ပုံများဖြင့် အာမခံတိုင်ကြားမှုများနှင့် အန္တရာယ်စီမံခန့်ခွဲမှုအတွက် စစ်ဆေးမှုလမ်းကြောင်းကို ဖန်တီးပေးသည်။ စာရွက်မှတ်တမ်းများကို အသုံးပြုသည့် နေရာများထက် ဒစ်ဂျစ်တယ်မှတ်တမ်းများ ပြုလုပ်ထားသော အဆောက်အဦများသည် မျက်နှာပြင်နှင့် သက်ဆိုင်သော တာဝန်ယူမှုတိုင်ကြားမှုများကို ၂၃% ပိုမြန်စွာ ဖြေရှင်းနိုင်ကြသည် (အားကစားနေရာ အန္တရာယ်စီမံခန့်ခွဲမှု အစီရင်ခံစာ ၂၀၂၄)။ စံချိန်စံညွှန်းထားသော အစီရင်ခံချက်တွင် ပါဝင်သင့်သည်မှာ-

- ပျက်စီးမှု တိုးတက်မှုအချိန်ဇယား

- ပြင်ဆင်မှုနည်းလမ်း ထိရောက်မှုအဆင့်သတ်မှတ်ချက်များ

- ရာသီအလိုက် စွမ်းဆောင်ရည် စံချိန်စံညွှန်းများ

ဤဒေတာသည် ထိန်းသိမ်းမှုဘတ်ဂျက်များကို ပိုမိုကောင်းမွန်စေပြီး၊ ကြိုတင်ခန့်မှန်းသော ဆုံးဖြတ်ချက်ချမှတ်မှုများကို အသုံးပြုသည့် နေရာများသည် မျက်နှာပြင်၏ သက်တမ်းကို ပျမ်းမျှအားဖြင့် ၂.၇ နှစ်အထိ တိုးမြှင့်နိုင်ပြီး စတုရန်းပေလျှင် တစ်နှစ်လျှင် ၁၂ မှ ၁၈ ဒေါ်လာအထိ ထိန်းသိမ်းမှုကုန်ကျစရိတ်ကို လျှော့ချနိုင်သည်။

ပြေးလမ်း၏ သက်တမ်းကို အများဆုံးဖြစ်အောင် ကာကွယ်ထိန်းသိမ်းမှု ဗျူဟာများ

ရေရှည်ပြုပြင်ထိန်းသိမ်းမှု ကုန်ကျစရိတ်ကို လျှော့ချရန် အစီအစဉ်ရှိသော ထိန်းသိမ်းမှု အစီအစဉ်ချမှတ်ခြင်း

အစီအစဉ်ရှိသော ထိန်းသိမ်းမှု ပြက္ခဒိန်သည် ကုန်ကျစရိတ်များသော တုံ့ပြန်ပြုပြင်မှုများကို ကာကွယ်ပေးပြီး၊ ၇၂% သော အဆောက်အဦးစီမံခန့်ခွဲသူများသည် အစီအစဉ်ရှိသော ထိန်းသိမ်းမှုများကို အသုံးပြုခြင်းဖြင့် နှစ်စဉ် ထိန်းသိမ်းမှုကုန်ကျစရိတ်များ လျော့ကျကြောင်း (Sports Surface Journal 2023) တွင် ဖော်ပြထားပါသည်။ အဓိက ပါဝင်မှုများမှာ အောက်ပါတို့ဖြစ်သည်-

- အစောပိုင်း ပျက်စီးမှုပုံစံများကို ရှာဖွေတွေ့ရှိရန် သုံးလတစ်ကြိမ် မျက်နှာပြင်စစ်ဆေးမှုများ

- ရေစိမ့်ဝင်မှုကို ကာကွယ်ရန် နှစ်နှစ်တစ်ကြိမ် ဆူးကြားပြန်လည်ပိတ်ဆို့ခြင်း

- အသုံးပြုမှု စံချိန်စံညွှန်းများအပေါ် အခြေခံ၍ ၈ မှ ၁၂ နှစ်တိုင်းတစ်ကြိမ် မျက်နှာပြင်ပြန်ဖုံးအုပ်ခြင်း

- ပွဲများပြီးနောက် ချက်ချင်း အမှိုက်အိမ်မဲ့များ ဖယ်ရှားခြင်း လုပ်ထုံးလုပ်နည်းများ

NCAA ပြေးလမ်း ထိန်းသိမ်းမှု ဘတ်ဂျက်များကို ၂၀၂၄ ခုနှစ်တွင် လေ့လာသုံးသပ်မှုအရ ရာသီအလိုက် ထိန်းသိမ်းမှု အစီအစဉ်များကို အကောင်အထည်ဖော်သည့် အဆောက်အဦးများသည် တုံ့ပြန်ပြုပြင်ထိန်းသိမ်းမှု နည်းလမ်းများနှင့် နှိုင်းယှဉ်ပါက တစ်နှစ်လျှင် ပျမ်းမျှ $18k ကို စုဆုံးနိုင်ကြောင်း ဖော်ပြထားပါသည်။

လမ်းကြောင်းအသုံးပြုမှုများသော အားကစားနှင့် ကျန်းမာရေး စောင့်ရှောက်မှုဆိုင်ရာ စခန်းများတွင် ကာကွယ်ကုသမှု၏ အကျိုးအမြတ်

ပြည်သူ့အသုံးပြုမှုရှိသော ပြေးလမ်းများကို လေ့လာထားသည့် ငါးနှစ်တာ သုတေသနစီမံကိန်းအရ ပြေးလမ်းကို ပုံမှန်ထိန်းသိမ်းရန် ဒေါ်လာတစ်ဒေါ်လာသာ သုံးစွဲခြင်းဖြင့် နောက်ပိုင်းတွင် ပြန်လည်တည်ဆောက်ရမည့်အခါ ဒေါ်လာ ၄.၃၀ ခန့် ခြွေတာနိုင်ပါသည်။ လူသွားလာမှုများသော အဆောက်အဦများသည် အပတ်စဉ် စစ်ဆေးမှုများ ပြုလုပ်ခြင်း၊ ရေထွက်ပေါက်များကို ကောင်းစွာလုပ်ဆောင်စေခြင်းနှင့် လူများလမ်းလျှောက်ခြင်း သို့မဟုတ် ပြေးခြင်းများအစား အားကစားလုပ်ဆောင်မှုများအတွက်သာ အသုံးပြုခွင့်ပေးခြင်းတို့ကို ပြုလုပ်ပါက ပိုမိုကြာရှည်စွာ ခံနိုင်ရည်ရှိပါသည်။ ထိုကွာခြားမှုမှာ သိသိသာသာရှိပြီး ကောင်းစွာထိန်းသိမ်းထားသော ပြေးလမ်းများသည် ဂရုစိုက်မှုနည်းပါးသော ပြေးလမ်းများထက် လုပ်ဆောင်နိုင်မှုကာလ ၄၀ ရာခိုင်နှုန်းခန့် ပိုမိုကြာရှည်ပါသည်။ အလယ်ပိုင်းဒေသရှိ တက္ကသိုလ်တစ်ခုကို ဥပမာထားပါမည်။ ၎င်းတို့သည် ပြဿနာကြီးမားလာမည့်အစား အက်ကြောင်းငယ်များကို အချိန်မီပြင်ဆင်ခြင်းနှင့် ရာသီအလိုက် အလွှာအသစ်များဖြင့် ပြန်လည်ဖုံးအုပ်ပေးခြင်းဖြင့် ၎င်းတို့၏ ပြေးလမ်း၏ အသုံးဝင်သော သက်တမ်းကို နှစ် ၅.၅ နီးပါးအထိ တိုးမြှင့်နိုင်ခဲ့ပါသည်။ ထိုသို့ဖြင့် မူလအတိုင်း အသစ်အဆန်းများကို ဝယ်ယူရန် လိုအပ်မည့် ဒေါ်လာ ၂၅၀,၀၀၀ ခန့်ကို ခြွေတာနိုင်ခဲ့ပါသည်။

ပြိုင်ပွဲလမ်းကြောင်း၏ ခံနိုင်ရည်ကို ထိန်းသိမ်းရန် အသုံးများသော ဧရိယာများကို ပြင်ဆင်ခြင်း

အတွင်းဘက်လမ်းကြောင်းများ၊ စတင်သော မျဉ်းများနှင့် ကွင်းဆင်းပြိုင်ပွဲဇုန်များအတွက် ဦးတည်ထားသော ပြင်ဆင်မှုများ

အားကစားကွင်းများ၏ အသုံးအများဆုံးနေရာများကို လစဉ်သုံးကြိမ်ခန့် ပုံမှန်စစ်ဆေးပြင်ဆင်ရန် လိုအပ်ပါသည်။ အတွင်းဘက်လမ်းကြောင်းများသည် အပြင်ဘက်လမ်းကြောင်းများထက် နေ့စဥ်အသုံးပြုသူ ၃၀% ခန့် ပိုများပြီး ပိုမိုပြင်းထန်စွာ ထိခိုက်မှုရှိပါသည်။ စတင်သောတိုင်များနှင့် ကွင်းဆင်းပြိုင်ပွဲနေရာများတွင်လည်း အချိန်ကြာလာသည်နှင့်အမျှ ပျက်စီးမှုများ သိသိသာသာ ပေါ်ပေါက်လာပါသည်။ ပျက်စီးမှုအများဆုံးကို ဘာကဖြစ်စေသနည်း။ အလွန်ပြင်းထန်သော အားဖြင့် ရှေ့သို့ ပြေးထွက်သည့် ပြေးသမားများက ၎င်းတို့၏ မျက်နှာပြင်ပေါ်တွင် စတုရန်းပေ ၅၀၀ ခန့် ဖိအားကို ဖန်တီးပေးပါသည်။ ထို့အပြင် လေ့ကျင့်ခန်းများအတွင်း မြေပြင်ပေါ်တွင် ကိရိယာများ ဆွဲ dragging ခြင်းလည်း ပါဝင်ပါသည်။ နေရာများသည် ပျက်စီးနေပုံ စတင်ပေါ်လာပါက ပြင်ဆင်မှုမပြုမီ ပျက်စီးနေသော အပေါ်ယံအလွှာကို အရင်ဆုံး ဖယ်ရှားသင့်ပါသည်။ ပြီးလျှင် ရာဘာပစ္စည်းများဖြင့် ထပ်မံဖုံးအုပ်ပေးပါ။ ဖိနှိပ်မှုများကြောင့် ဖိစီးမှုများ ပေါ်ပေါက်နေသော နေရာများကို ဦးစားပေးပြီး အကွာအဝေး ၆ လက်မမှ ၁၂ လက်မအထိ အကွက်လိုက် စက်ဝိုင်းပုံစံဖြင့် ပြင်ဆင်ခြင်းက အကောင်းဆုံးရလဒ်ကို ရရှိစေပါသည်။

ကွဲအက်မှုများကို ပိတ်ဆို့ခြင်းနှင့် ဖွဲ့စည်းတည်ဆောက်ပုံ ခိုင်မာမှုအတွက် ကျွမ်းကျင်သူများနှင့် တိုင်ပင်ဆွေးနွေးခြင်း

လက်ခြောက်လက်မထက်ပိုသော ကွဲအက်မှုများကို ထားခဲ့ပါက ရေများစိမ့်ဝင်နိုင်ပြီး Pavement Preservation Journal မှ လေ့လာမှုများအရ များသောအားဖြင့် ရှိသည့် ရေခဲ-အပူချိန်ပြောင်းလဲမှု ဖြစ်စဉ်များတွင် မြေအောက်ပျက်စီးမှုအန္တရာယ်ကို သုံးဆတိုးစေနိုင်ကြောင်း တွေ့ရှိရပါသည်။ ထိုကွဲအက်မှုများကို တွေ့ရှိပါက အပူပေါင်းသတ္တိပါသော ပိတ်ဆို့ရန်ပစ္စည်း (thermoplastic sealant) ကို အမြန်ဆုံး အသုံးပြုသင့်ပြီး အကောင်းဆုံးမှာ သုံးရက်အတွင်းတွင် ပြုပြင်သင့်ပါသည်။ ပြုပြင်မှုသည် ပတ်ဝန်းကျင်ရှိ မျက်နှာပြင်နှင့် ချောမွေ့စွာ ပေါင်းစပ်နေရမည်ဖြစ်ပြီး လမ်းပေါ်တွင် လျှောက်လှမ်းသူများအတွက် ခြေလှမ်းအန္တရာယ် မဖြစ်စေရန် အများဆုံး ဒီဂရီ ၁၅ ထက် မပိုစေရပါ။ တစ်ပတ်လျှင် ဧည့်သည် တစ်ထောင်ကျော် လာရောက်သော အဆောက်အအုံများအတွက် တစ်နှစ်လျှင် တစ်ကြိမ် အတွေ့အကြုံရှိသော လမ်းကြောင်းအင်ဂျင်နီယာနှင့် ပူးပေါင်းဆောင်ရွက်ခြင်းသည် အကျိုးရှိပါသည်။ ဤကျွမ်းကျင်သူများသည် အောက်ခြေအလွှာများ မည်မျှကျစ်လျစ်မှုရှိသည်ကို စစ်ဆေးပေးပြီး အလွှာများကြားရှိ ရေထွက်စနစ်များ ကောင်းစွာလုပ်ဆောင်နေမှုရှိမရှိ သေချာစေပါသည်။

ဥပမာလေ့လာမှု - တက္ကသိုလ်တစ်ခုသည် ကြိုတင်ပြုပြင်ထိန်းသိမ်းမှုများဖြင့် လမ်းကြောင်းသက်တမ်းကို ၅ နှစ်တိုးတက်အောင် ဆောင်ရွက်နိုင်ခဲ့ခြင်း

အနောက်အလယ်ပိုင်း တက္ကသိုလ်တစ်ခုက အားကစားဌာနတစ်ခုဟာ အနီအောက် စကင်နင်းနည်းပညာကို သုံးပြီးနောက် ထိန်းသိမ်းရေးကုန်ကျစရိတ်ကို ၄၀ ရာခိုင်နှုန်းလောက် လျှော့ချနိုင်ခဲ့တယ်။ ဒီစကင်တွေက မျက်နှာပြင်အောက်မှာ မြင်သာတဲ့ ပျက်စီးမှုအဖြစ် မပေါ်ခင်မှာ ပုန်းနေတဲ့ တည်ဆောက်မှု ပြဿနာတွေကို ရှာဖွေဖို့ ကူညီပေးခဲ့တယ်။ ပြေးလမ်းကို မသုံးတဲ့ ရာသီအတွင်း လိုအပ်တဲ့ ပြင်ဆင်မှုတွေ စီစဉ်ပေးခြင်းနဲ့ အပူဓာတ်ပုံရလဒ်တွေကို အားကိုးခြင်းအားဖြင့် အဆောက်အအုံဟာ ပြေးလမ်းရဲ့ သက်တမ်းကို ၁၂ နှစ်ကနေ ၁၇ နှစ်အထိ တိုးချဲ့နိုင်ခဲ့တယ်။ ဒါကတော့ ၂၀၂၃ ခုနှစ်မှာ Facilities Management Quarterly မှာ ထုတ်ဝေခဲ့တဲ့ အစီရင်ခံစာအရ ခြေလှမ်းကို လုံးဝ ပြန်လည်တည်ဆောက်ဖို့ သုံးခဲ့မှာမဟုတ်တဲ့ ဒေါ်လာ ၃၈၀,၀၀၀ လောက်ကို ချွေတာဖို့ ဆိုလိုတာပါ။

အဓိက ထိန်းသိမ်းရေး မဟာဗျူဟာ :

| ကြားဝင်မှု | အကြိမ်နှုန်း | ဘီးလမ်းကြောင်း သက်တမ်းရှည်ခြင်းအပေါ် သက်ရောက်မှု |

|---|---|---|

| အက်ကြောင်းပိတ်ခြင်း | ရှာဖွေတွေ့ရှိပြီး ၇၂ နာရီအတွင်း | မြေအောက်ရေပျက်စီးမှု ၈၃% ကို ကာကွယ်ပေးတယ်။ |

| အနီအောက် စကင်များ | နှစ်စဉ်နှစ်တိုင်း | ဝှက်ထားတဲ့ ချို့ယွင်းချက် ၉၅% ကို အစောပိုင်းမှာ ရှာဖွေနိုင်တယ် |

| ရာဘာအက်ပ် | ယာဉ်ကြောများတဲ့ နေရာတွေမှာ သုံးလပတ် | မျက်နှာပြင် ဆွဲခြင်းအလွှာ အသုံးပြုနှုန်းကို ၅၅% လျော့ကျစေသည် |

ဤအဆင့်ဆင့် ချဉ်းကပ်မှုသည် ပြုပြင်ထိန်းသိမ်းမှု ကုန်ကျစရိတ်ကို အဖွဲ့အစည်း၏ ဘတ်ဂျက်များနှင့် ကိုက်ညီစေရန် အတွက် ပြေးလမ်း၏ စံပြအလုပ်လုပ်မှုကို သေချာစေပါသည်။

ပြေးလမ်း ထိပ်အလွှာပြန်ဖုံးခြင်း - အပြည့်အဝ အစားထိုးခြင်းမရှိဘဲ စီးပွားဖြစ် ပြန်လည်နိုးထမှု

အပြည့်အဝ ပြန်လည်တည်ဆောက်ခြင်း၏ ရေရှည်တည်တံ့သော အစားထိုးနည်းလမ်းအဖြစ် ထိပ်အလွှာပြန်ဖုံးခြင်း

လမ်းကြောင်းများ၏ မျက်နှာပြင်များတွင် သုံးစွဲမှုကြောင့် ပျက်စီးမှုများ စတင်ပေါ်လာပါက ၎င်းတို့ကို အပြည့်အဝ အစားထိုးခြင်းအစား ပြန်လည်ဖုံးအုပ်ခြင်း (re-topping) ပြုလုပ်ခြင်းဖြင့် ပစ္စည်းအသုံးပြုမှု အကုန်ကျခြင်းကို အနည်းဆုံး ၆၀% ခန့် လျှော့ချနိုင်ပါသည်။ ထို့အပြင် ထိုကဲ့သို့သော လမ်းကြောင်းများသည် နောက်ထပ် ပြုပြင်မွမ်းမံမှုတစ်ခု လိုအပ်သည်အထိ ၇ နှစ်မှ ၁၀ နှစ်အထိ ပိုမိုကြာရှည်စွာ ခံနိုင်ရည်ရှိလေ့ရှိပါသည်။ ဤနည်းလမ်းသည် အခြေခံအုတ်မြစ် အနေအထား ကောင်းမွန်စွာ ရှိနေသေးသည့်အချိန်တွင် ယခင်အုတ်မြစ်ပေါ်တွင် ပေါ်လီယူရီသိန်း (polyurethane) သို့မဟုတ် လက်တက် (latex) အလွှာအသစ်များကို ဖုံးအုပ်ခြင်းဖြစ်ပါသည်။ ဤချဉ်းကပ်မှုသည် အားကစား facilities များတွင် ရေရှည်တည်တံ့မှုနှင့် အားကစားအခြေခံအဆောက်အအုံများတွင် စက်ဝိုင်းပုံစံစီးပွားရေး (circular economy) မူများ အသုံးပြုခြင်းနှင့် ပတ်သက်၍ ၂၀၂၄ ခုနှစ်တွင် ထုတ်ပြန်ခဲ့သော စာတမ်းတွင် ဖော်ပြထားသည့်အတိုင်း ကိုက်ညီပါသည်။ အများအားဖြင့် စီမံခန့်ခွဲသူများသည် အောက်ပါ အကျိုးကျေးဇူးနှစ်ခုကို တစ်ပြိုင်နက် ရရှိသောကြောင့် ဤနည်းလမ်းကို ရွေးချယ်လေ့ရှိပါသည်။ ပထမအနေဖြင့် အစားလိုက်ပြီး အသစ်တစ်ခုလုံး တည်ဆောက်ခြင်းထက် ကနဦးကုန်ကျစရိတ်မှာ အနည်းဆုံး ၄၀% လျော့နည်းပါသည်။ ဒုတိယအနေဖြင့် ပြုပြင်ထိန်းသိမ်းမှုအတွင်း အနားယူရသည့်ကာလ (downtime) သည် လုံးဝပြန်လည်တည်ဆောက်ခြင်းတွင် ဖြစ်ပေါ်လေ့ရှိသည့် အချိန်၏ ၂၅% အောက်တွင်သာ ရှိသောကြောင့် လုပ်ငန်းဆောင်တာများတွင် အနှောက်အယှက် အလွန်နည်းပါးပါသည်။

ဒေတာအချက်အလက် - လမ်းကြောင်းကို အသုံးပြုပြီး ၁၀ နှစ်အတွင်း ကျောင်းများ၏ ၇၀% သည် ပြန်လည်ဖုံးအုပ်ခြင်း (re-topping) ကို ရွေးချယ်ကြသည်

ကိန်းဂဏန်းတွေကို ကြည့်လိုက်ရင် မျက်နှာပြင်တွေကို ပြန်လည်အခေါက်လိုက်ခြင်းဟာ တစ် စတုရန်းမီတာကို ၁၅ နှစ်ကြာ ကုန်ကျစရိတ်ကို ထည့်တွက်တဲ့အခါမှာ အပြည့်အဝ အစားထိုးတာနဲ့ယှဉ်ရင် သုံးတဲ့ ဒေါ်လာတိုင်းမှာ ၈၂ ဆင့်လောက် ချွေတာပါတယ်။ မြို့နယ် အားကစားကွင်းတွေနဲ့ မူကြိုကနေ အထက်တန်းကျောင်းအထိ ကျောင်းတွေဟာ ဒီဗျူဟာကို တကယ်ကို စွဲကိုင်ထားတယ်။ ပညာရေး အဖွဲ့အစည်း ၁၀ ခုမှာ ၇ ခုက ကစားကွင်းတွေ တပ်ဆင်ပြီး ဆယ်စုနှစ်ပြည့်သွားတာနဲ့ ကစားကွင်းတွေကို လုံးဝ အစားထိုးတာထက် ပြန်လည်ပြင်ဆင်ဖို့ ရွေးကြတယ်။ ဒီမှာ မြင်နေတာက ပိုတော်တဲ့ ထိန်းသိမ်းမှု လုပ်ထုံးလုပ်နည်းတွေဆီ ပိုကြီးမားတဲ့ အပြောင်းအလဲရဲ့ အစိတ်အပိုင်းပါ။ ကျောင်းတွေနဲ့ မြို့တွေဟာ သူတို့ရဲ့ ဘတ်ဂျက်တွေကို ဘယ်လို တိုးချဲ့မလဲဆိုတာ စဉ်းစားနေကြပြီး တစ်ချိန်တည်းမှာ နေ့စဉ် ဒီနေရာတွေကို သုံးကြတဲ့ အားကစားသမားတွေအတွက် လုံခြုံရေး စံနှုန်းတွေကို ထိန်းထားနေကြတယ်။

FAQ အပိုင်း

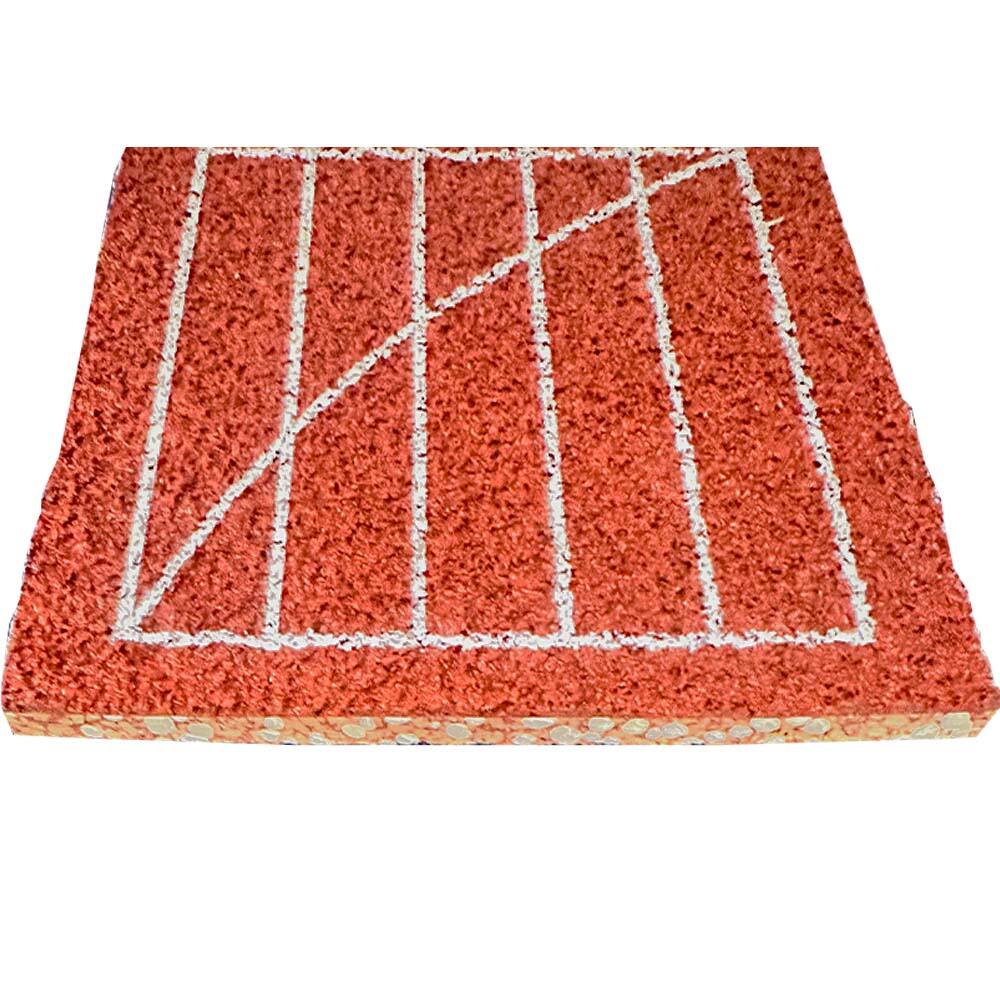

[စာမျက်နှာ ၂၇ ပါ ရုပ်ပုံ]

ပုံမှန်သန့်စင်ခြင်းက အမှိုက်တွေ စုစည်းမှုကို တားဆီးပေးပြီး မျက်နှာပြင်ပျက်စီးစေပြီး လမ်းကြောင်းပေါ်က အဝတ်လျှော်မှုကို တိုးစေနိုင်ပြီး နောက်ဆုံးတွင် ၎င်း၏ သက်တမ်းကို သက်တမ်းတိုးစေပြီး ထိန်းသိမ်းမှုကုန်ကျစရိတ်ကို လျှော့ချပေးပါတယ်။

သင့်ရဲ့ ရေအိုးများကို မည်သို့ထိန်းသိမ်းပေးရမလဲ။

လစဉ်အပြင်ဘက်ရေအိုးများနှင့် ရေကောက်ခံသည့်နေရာများကို ရှင်းလင်းစွာထားပါ။ တစ်နှစ်လျှင် ခြောက်ကြိမ် မြေအောက်ပိုက်လိုင်းများကို ကင်မရာဖြင့်စစ်ဆေး၍ ရေအိုးများကို ကောင်းစွာထိန်းသိမ်းပါ။

စနစ်တကျ ထိန်းသိမ်းမှု ပြက္ခဒိန်၏ အကျိုးကျေးဇူးများမှာ အဘယ်နည်း။

စနစ်တကျ ထိန်းသိမ်းမှု ပြက္ခဒိန်သည် ကုန်ကျစရိတ်များသော တုံ့ပြန်ပြုပြင်မှုများကို ကာကွယ်ပေးပြီး နှစ်စဉ် ထိန်းသိမ်းမှုစရိတ်များကို လျှော့ချပေးကာ ကြိုတင်ထိန်းသိမ်းမှုဖြင့် လမ်းကြောင်း၏ သက်တမ်းကို ရှည်လျားစေပါသည်။

အပေါ်ယံပြန်ဖုံးခြင်းသည် အပြည့်အဝအစားထိုးခြင်းနှင့် မည်သို့ကွာခြားပါသနည်း။

အပေါ်ယံပြန်ဖုံးခြင်းတွင် ရှိပြီးသားအောက်ခံပေါ်တွင် အလွှာအသစ်များ ထပ်ဖုံးခြင်းဖြစ်ပြီး ပစ္စည်းအ waste နှင့် ကုန်ကျစရိတ်များကို လျှော့ချပေးကာ အပြည့်အဝအစားထိုးခြင်းထက် လမ်းကြောင်း၏ သက်တမ်းကို ၇ မှ ၁၀ နှစ်အထိ ရှည်လျားစေပါသည်။ အပြည့်အဝအစားထိုးခြင်းမှာ ပိုမိုနှောင့်ယှက်မှုရှိပြီး ကုန်ကျစရိတ်ပိုများပါသည်။

အကြောင်းအရာများ

- ပြေးလမ်းမျက်နှာပြင်၏ တည်ငြိမ်မှုကို ထိန်းသိမ်းရန် ပုံမှန်သန့်ရှင်းခြင်း

- ပြေးလမ်းကြောင်းပျက်စီးမှုများကို စောစီးစွာ ရှာဖွေတွေ့ရှိရန် ပုံမှန်စစ်ဆေးခြင်း

- ပြေးလမ်း၏ သက်တမ်းကို အများဆုံးဖြစ်အောင် ကာကွယ်ထိန်းသိမ်းမှု ဗျူဟာများ

-

ပြိုင်ပွဲလမ်းကြောင်း၏ ခံနိုင်ရည်ကို ထိန်းသိမ်းရန် အသုံးများသော ဧရိယာများကို ပြင်ဆင်ခြင်း

- အတွင်းဘက်လမ်းကြောင်းများ၊ စတင်သော မျဉ်းများနှင့် ကွင်းဆင်းပြိုင်ပွဲဇုန်များအတွက် ဦးတည်ထားသော ပြင်ဆင်မှုများ

- ကွဲအက်မှုများကို ပိတ်ဆို့ခြင်းနှင့် ဖွဲ့စည်းတည်ဆောက်ပုံ ခိုင်မာမှုအတွက် ကျွမ်းကျင်သူများနှင့် တိုင်ပင်ဆွေးနွေးခြင်း

- ဥပမာလေ့လာမှု - တက္ကသိုလ်တစ်ခုသည် ကြိုတင်ပြုပြင်ထိန်းသိမ်းမှုများဖြင့် လမ်းကြောင်းသက်တမ်းကို ၅ နှစ်တိုးတက်အောင် ဆောင်ရွက်နိုင်ခဲ့ခြင်း

- ပြေးလမ်း ထိပ်အလွှာပြန်ဖုံးခြင်း - အပြည့်အဝ အစားထိုးခြင်းမရှိဘဲ စီးပွားဖြစ် ပြန်လည်နိုးထမှု

- FAQ အပိုင်း

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

SV

SV

CA

CA

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

MN

MN

MY

MY

UZ

UZ