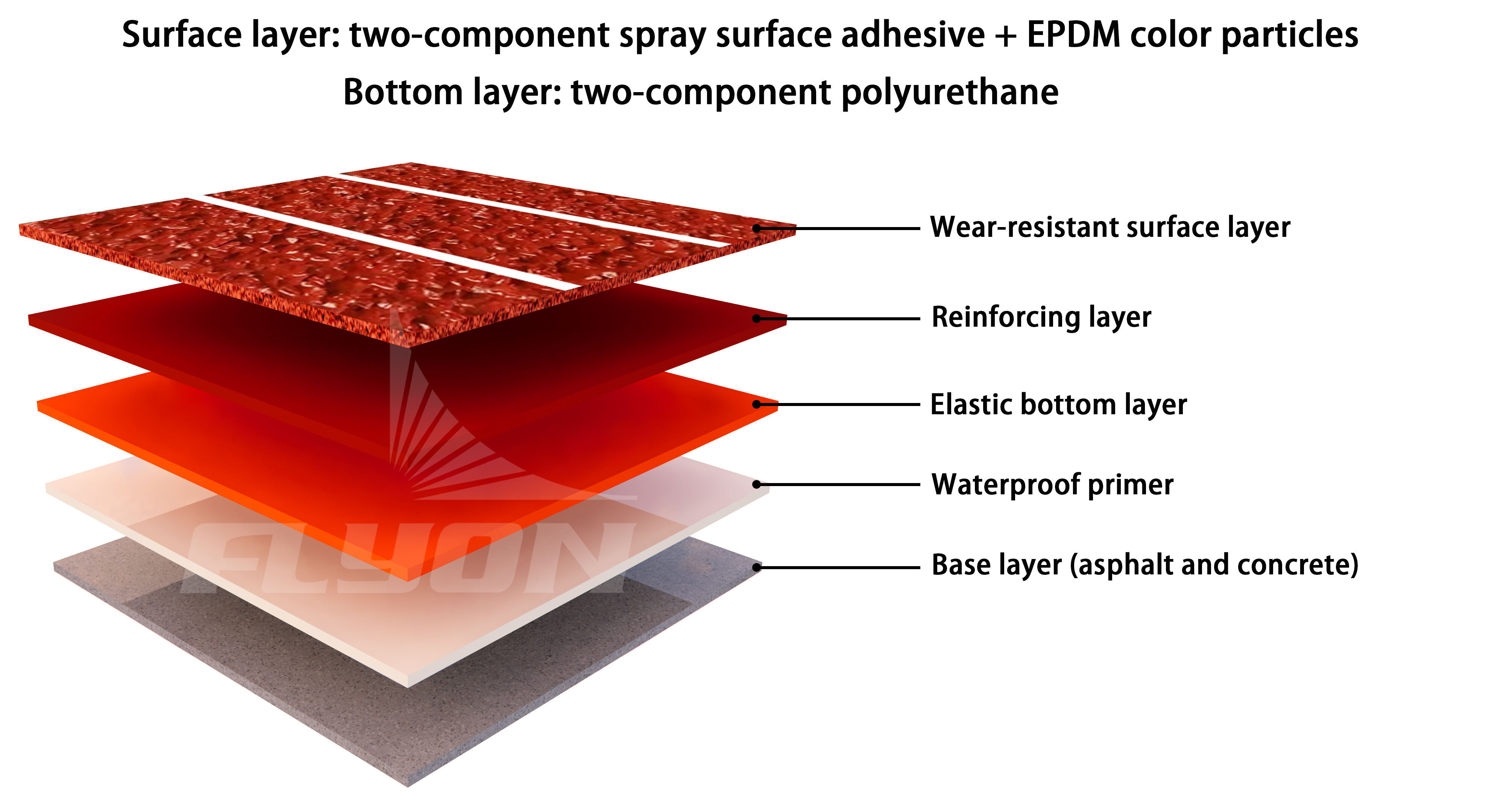

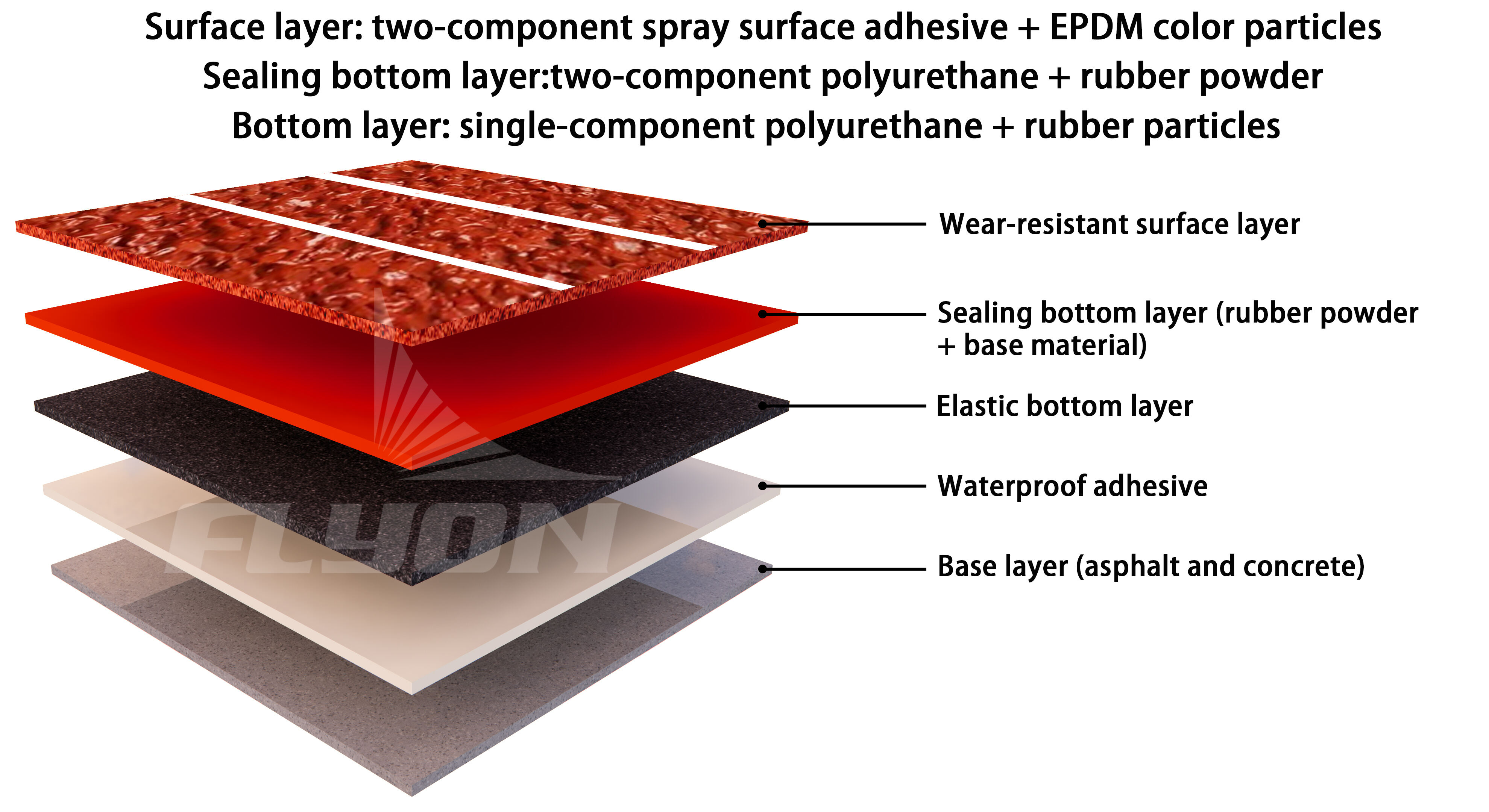

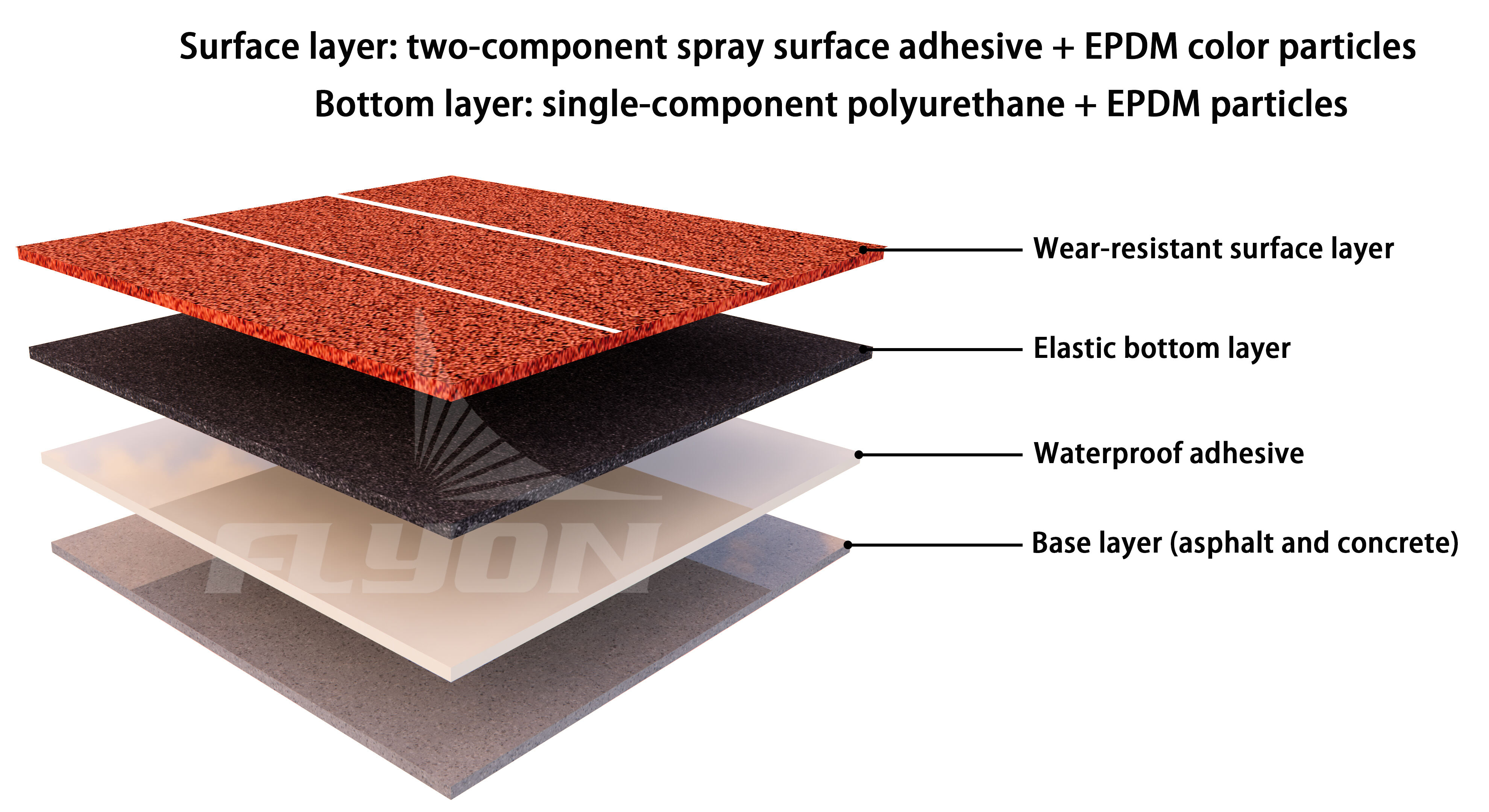

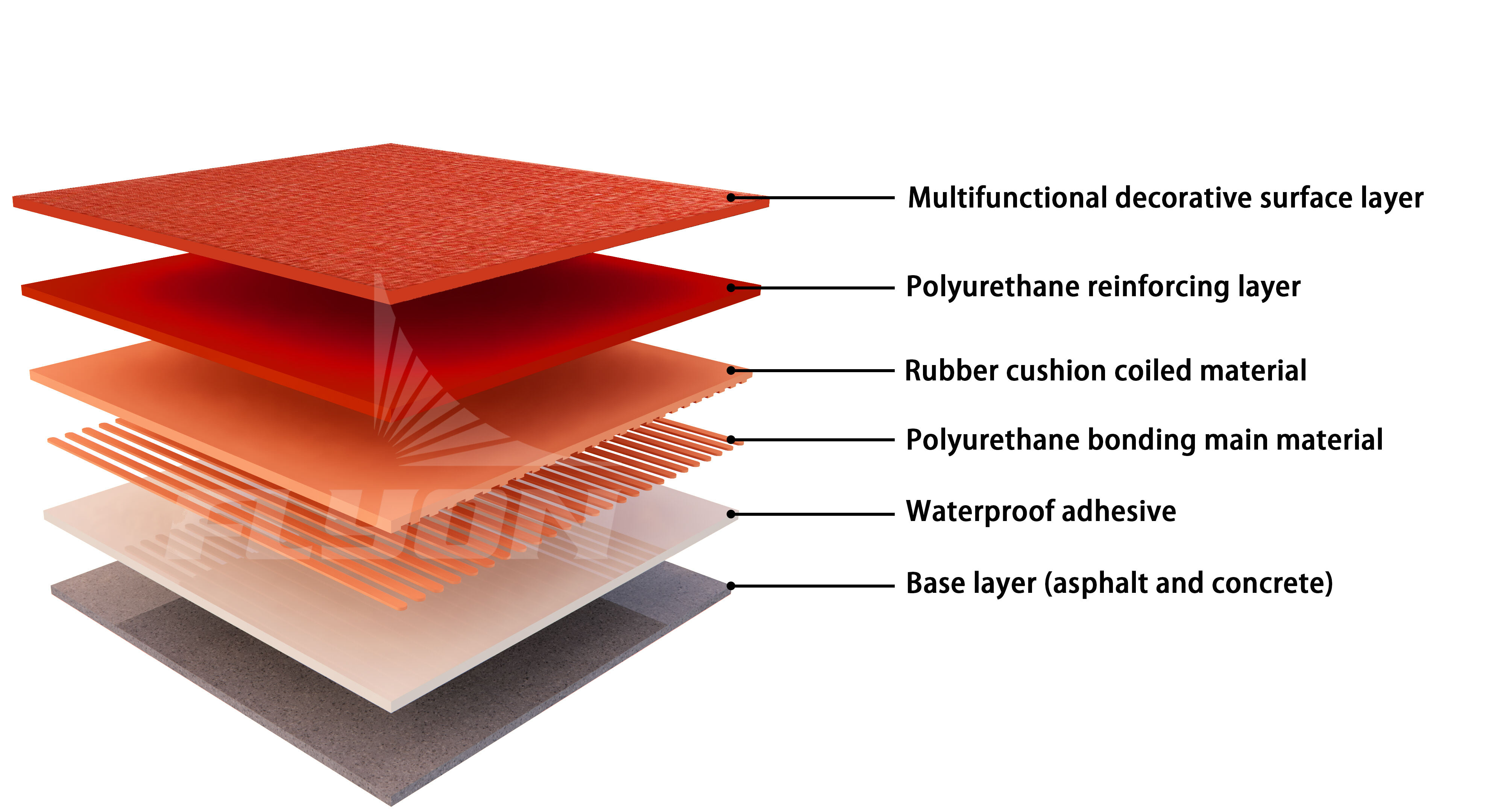

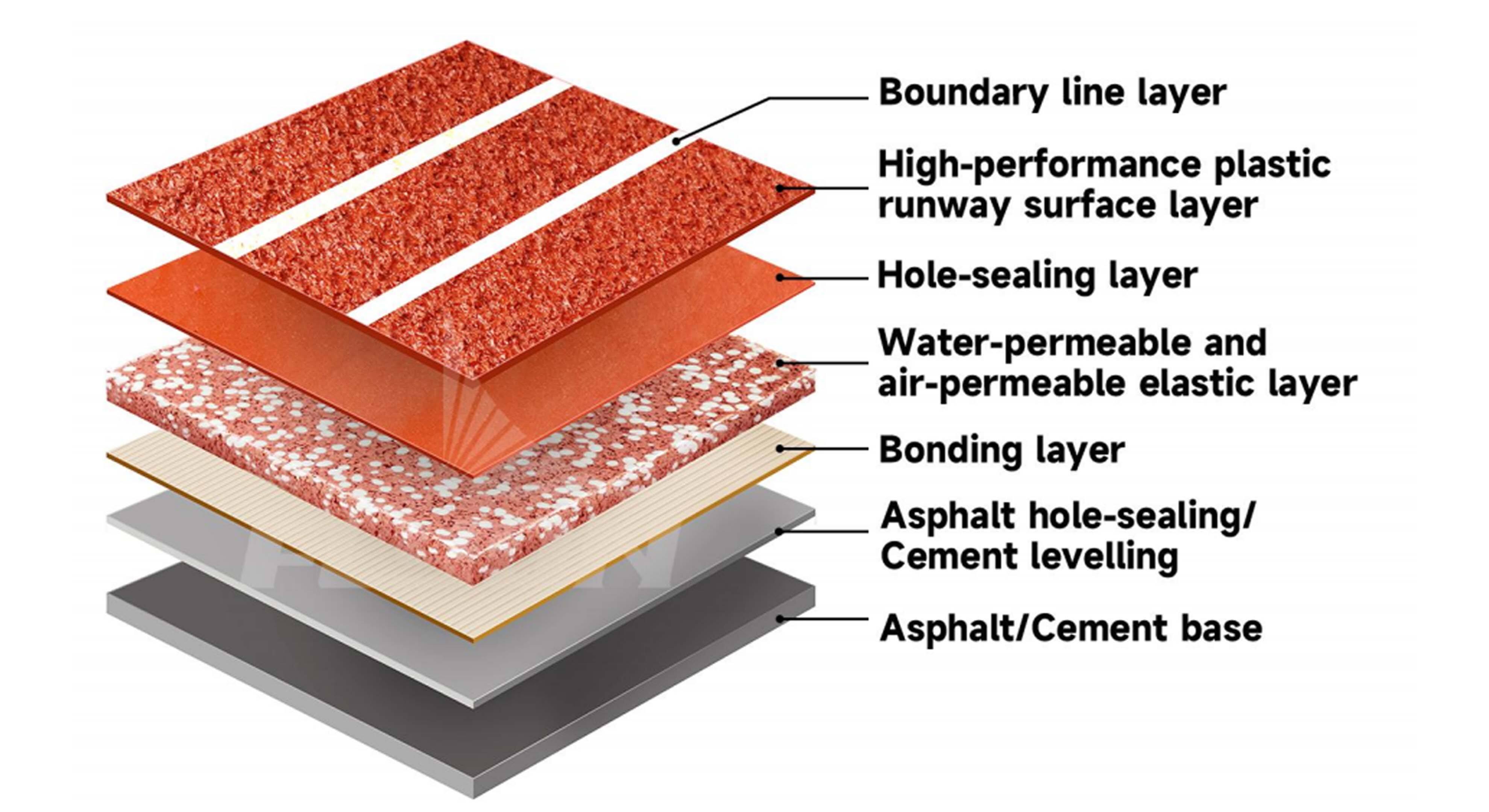

Semi-prefabricated rubber runways are a type of runway that is partially prefabricated in the factory and then completed on-site. They consist of a high-performance rubber surface layer, an elastic cushioning layer, and an adhesive layer that bonds the system to the foundation. The cushioning layer is typically made of porous rubber or composite materials for optimal shock absorption.

It has the following advantages:

● Excellent shock absorption and energy return for enhanced athletic performance.

● Highly durable and resistant to weathering, UV rays, and heavy use.

● Available in multiple colors and designs for customization.

● Faster installation than traditional systems with easier maintenance.

Specification

Product Name |

Semi-Prefabricated System Running Track |

Feature |

Semi-Prefabricated for easy installation, great sports performance, safe, eco-friendly |

Base |

Cement or asphalt |

Color |

Red, blue, yellow, grey and customized |

Thickness |

9-15.9MM(or customized) |

Warranty |

2 Years |

Certificate |

IAAF |

Application |

Stadium, sports ground, sport center, schools, jogging park and so on. |

Semi-prefabricated rubber runways combine factory-made rubber surface layers with on-site installed cushioning bases, offering professional-grade performance with easier installation than traditional poured systems.

✅ Rapid Installation - 400m track completed in 5-7 days with weather-resistant bonding technology

✅ Performance-Tuned Layers - Factory-engineered surface + site-optimized cushioning (1.5-3.0kN/m² adjustable)

✅ Seamless Integration - ≤1.0mm vertical transition between prefab and cast-in-place sections

✅ All-Climate Durability - Stable performance from -35°C to 55°C with thermal expansion control

✅ Smart Maintenance - Embedded wear indicators and modular repair system (30% faster than full-pour)

✅ Eco-Flex Design - 85% reusable materials with customizable base for different soil conditions

Application

• School & University Tracks

• Community Sports Facilities

• Professional Training Centers

• Temporary Event Venues

Project Efficiency

• 70% faster commissioning vs. traditional tracks

• Zero on-site curing or VOC emissions

• 5-minute modular replacement per damaged panel

• 25-year structural warranty on interlock system

Professional Services

• CAD-based track layout design

• On-site base preparation consultation

• Year 1/5/10 maintenance programs

• Customized sport line marking packages

• Installation Service

With 20 years of installation experience, our installation team are capable of IAAF line marking with certificate. Engineers can be dispatched to any country for on-site installation guidance.

Company Project

Installation Machine

Our Factory

Flyon Sport with 20 years experience in Sports facility products, install over 1000 project in all over the word, provide sports equipment to Olympic games ,world cup and some national stadium,really good reputation in the sports industry.

Send us the link of the product you are interested in to discuss further details, such as the price and shipping costs. We are looking forward to your message and establishing a friendly and cooperative working relationship.

Certificate

FAQ