Spatial Flexibility: Modular Tartan Track Configurations

Overcoming Spatial Constraints in Multipurpose Halls

Tartan tracks made from modular panels can turn pretty much any awkward space into something athletes will love. Think about those old school gyms, community halls, or even factories that have been converted for other uses. These systems work differently from the standard poured rubber stuff because they fit around all sorts of obstacles. Pillars? No problem. Sloped ceilings? Just adjust the panels. Doorways and shared walls? The system bends around them without needing to tear anything down. For places with historical significance or tight budgets, this matters a lot since nobody wants to spend months waiting for construction or dealing with demolition costs. Facility managers across the country are seeing installation times cut by about 40 percent compared to regular poured surfaces. Some installations get finished in just over a week sometimes, which makes everyone involved pretty happy.

Poured vs. Sheet-Based Tartan: Installation Methods for Tight or Irregular Spaces

Two core installation approaches address spatial complexity, each with distinct advantages:

- Poured-in-place polyurethane excels on sites with elevation changes, curved perimeters, or integrated drainage systems. Its fluid application conforms seamlessly to contours—filling gaps beneath bleachers, wrapping around columns, or bridging transitions between track and field—and eliminates seams that compromise durability or safety.

- Pre-fabricated rubber sheets and interlocking tiles are ideal for tight indoor halls, offering precision trimming around obstacles and rapid, localized replacement of damaged sections—critical in high-traffic gyms or multi-sport facilities.

| Method | Best For | Installation Time | Adaptability |

|---|---|---|---|

| Poured Polyurethane | Sloped terrain, curved tracks | 3–5 weeks | High |

| Rubber Sheets | Tight corners, indoor venues | 1–2 weeks | Moderate |

Sheet-based systems require 30% less subfloor preparation in uneven or constrained areas, while poured polyurethane delivers superior gradient control—essential where tracks interface directly with natural or synthetic fields. Both methods meet World Athletics (formerly IAAF) force reduction standards when engineered to site-specific load and usage profiles.

Site-Specific Infrastructure Integration for Tartan Track Performance

Grading, Drainage, and Base Layer Customization by Venue Type

No two tartan tracks are built the same way because good groundwork depends heavily on where they're located and what they need to do. For outdoor tracks, getting the slope right matters a lot. Most need around 0.1% to 1% slope across them so water drains properly without building up pressure underneath the surface. This pressure buildup can actually cause blisters in the track material and lead to early wear problems. Indoor tracks have their own challenges too. They usually need vapor barriers installed deep down in the foundation to stop moisture from moving up through the layers. Without this protection, humidity can wreak havoc on the track structure especially in damp areas. Coastal locations face different issues altogether. Tracks near saltwater get built on crushed limestone bases since regular materials would corrode too fast. Places with volcanic soil tend to lay down special fabric mats beneath the track to keep the ground from sinking over time. How stormwater gets handled changes based on budget and location as well. Big stadiums might install massive underground storage tanks connected to city systems, but schools generally stick with simple swales around the edges of their tracks. These thoughtful adjustments actually make a real difference. Tracks constructed with these site-specific considerations last anywhere from 3 to 5 years longer than ones built with standard specifications.

Topography-Driven Track Planning: Orientation, Slope, and Alignment

Good track design works with nature rather than against it. Most competitive tracks run north to south because this cuts down on sun glare problems that can hurt athletes' eyes by around 40% according to several studies published in sports engineering journals. When building on hills, special lasers help grade the ground so the slope doesn't exceed World Athletics requirements of under 2%. This matters a lot for sprinters who need consistent footing across all lanes. For oddly shaped sites, designers often tweak curves or shorten corners while still keeping each lane at the right width and distance as required for official competitions. The drainage system gets placed where winds naturally blow, which helps dry wet surfaces faster after rain. Getting utilities mapped out early in the project is also smart planning since finding irrigation pipes or power lines later on usually causes expensive changes and time wasting delays nobody wants.

Application-Tailored Tartan Track Materials and Design

Performance Material Selection: Polyurethane, EPDM, and SBR for Sprint Lanes

Getting sprint lane materials right means finding that sweet spot between giving runners enough energy back when they push off and absorbing enough shock to keep their knees safe from damage. That's why most top level competitions use polyurethane bound systems these days. They just handle those little deformations better vertically and maintain consistent force reduction properties, something World Athletics labs have confirmed through testing. For outdoor tracks that get lots of sun exposure, EPDM granules stand out because they resist fading and stay colorful much longer than other options. Then there's SBR rubber which holds up pretty well against wear and tear while costing less money, so it works great for practice areas where people run around all day long. Some recent research done in 2023 looked at twelve different athletic centers and saw that tracks made with polyurethane had about 18 percent fewer leg injuries compared to older SBR surfaces. When picking materials for track construction, three main things matter most: how consistently spikes grip the surface, how well the material cushions impacts, and whether it expands or contracts too much with temperature changes throughout the day. This last factor becomes especially important in places where temperatures swing wildly from morning to night.

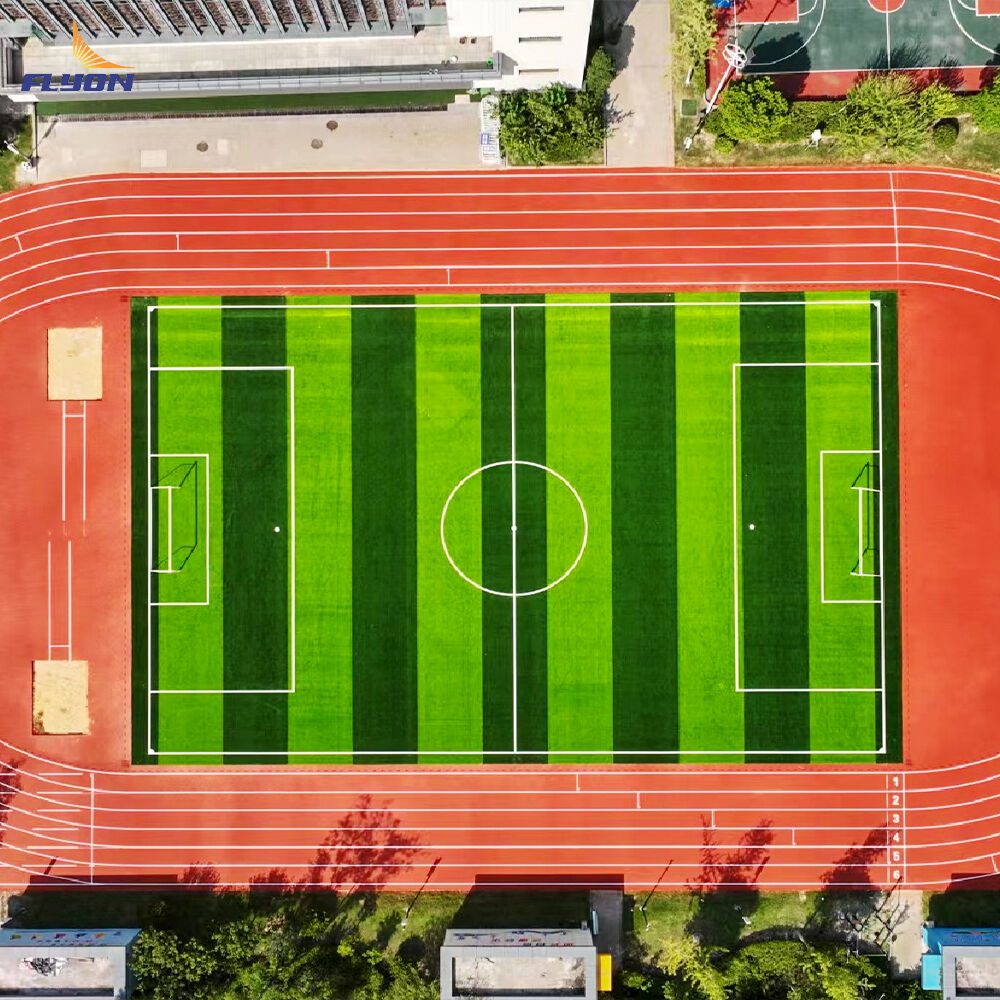

Venue-Specific Tartan Track Use Cases — Athletics, Schools, Gyms, and Multi-Use Fields

Choosing the right materials and systems depends on what the space will be used for, who will be using it, and how much maintenance can realistically be done. For competition tracks, getting World Athletics certified polyurethane surfaces isn't just about meeting standards - it actually affects whether records stand and how athletes perform biomechanically. Schools often go for those dual purpose designs with EPDM tops that meet EN 1177 safety standards for falls, plus they need binders that can withstand vandals since kids tend to mess around sometimes. Gym floors work best when we install those poured-in-place tartan systems that stick properly to surrounding hardwood or sprung floors. This prevents tripping hazards and gives trainers more usable space in all directions. Multi use fields typically have these hybrid setups where certain areas like soccer penalty boxes and rugby try zones get extra wear resistant layers, while the rest has good drainage for when rain comes down hard or cleats tear up the surface. Studies indicate that when facilities match their material thickness, binder choices, and granule mix to expected foot traffic levels, they end up extending the life of their surfaces by around 40%. Facility managers should really focus on three main things: making sure surfaces hold up against cleats, managing moisture issues especially near coastlines, and having sections that can be repaired individually instead of replacing whole areas whenever something gets damaged.

FAQ

What are modular tartan tracks?

Modular tartan tracks are flexible athletic surfaces made from panels that can be adjusted to fit around obstacles like pillars or sloped ceilings, ideal for converting awkward spaces.

What are the advantages of pre-fabricated rubber sheets over poured polyurethane?

Pre-fabricated rubber sheets offer precision trimming around obstacles and allow rapid replacement of damaged sections, making them suitable for tight indoor spaces and high-traffic areas.

What materials are recommended for outdoor sprint lanes?

Polyurethane-bound systems are recommended for outdoor sprint lanes due to their energy-efficient deformations and consistent force reduction properties, essential for runner safety.

How do tracks handle stormwater drainage?

Stormwater drainage may involve underground storage tanks for large stadiums or simple swales for schools, depending on budget and location.

EN

EN

AR

AR

FR

FR

PT

PT

RU

RU

ES

ES

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

RO

RO

SV

SV

CA

CA

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

AZ

AZ

KA

KA

BN

BN

LO

LO

MN

MN

MY

MY

UZ

UZ